A look into upcoming domain of 3D printing through Ryan Vaz-owned Infinyt 3D

By SAMAY SHETTI

The pace at which technology has progressed through innovation, since the discovery of silicon chip, has been unprecedented. Throughout that timeframe, certain technologies have come along which have completely changed the paradigms of both the worlds – of science and commerce. In the present time, this spot is effectively occupied by the technology of 3D Printing.

Observing this at the opportune time, Ryan Vaz started a new venture in the same domain. Infinyt 3D came into existence on 15th August 2014 in Verna and has since expanded its reach through varied domains, ranging from providing 3D printing services to setting up tech labs in schools.

Ryan talks about his journey in the domain and his motivations to venture onto it. A tool and die maker by qualification, he completed a course in the trade through Tool Room and Training centre Kundaim in June 2003. Following this, he started his first business in the same year – Dimensions, which dealt mainly in fabrication processes. The business was doing well; however, by 2010, the need to do something ‘new and different’ started playing on Ryan’s mind. “That was the time I stumbled upon 3D printing technology, popular back then as Rapid Prototyping,” he shares. Having started researching then, a lot of time went into deliberation of the same. “One thing that I realised that time was that I needed to pursue this – as this technology was here to stay and would greatly influence everybody’s lives,” says Ryan. “I felt that, if I am to enter, the time was now,” he adds. In 2014, he kickstarted the project with an investment of ₹2 Lakhs, by first booking a place to set up the business; and then placing an order for the first 3D printer, at the cost of ₹1.5 lakh. “The time was ripe, and it could not be put off further,” says Ryan. Being completely bootstrapped, the business looks to turn profitable this year.

Once started, Infinyt 3D went all out into exploring, researching about and experimenting with the machine, “I have a box full of failed experiments,” chuckles Ryan. “We needed to get as much understanding of the machine on our own, as there was nobody in Goa; and only a handful of professionals throughout India that time in this domain,” he shares.

Once started, Infinyt 3D went all out into exploring, researching about and experimenting with the machine, “I have a box full of failed experiments,” chuckles Ryan. “We needed to get as much understanding of the machine on our own, as there was nobody in Goa; and only a handful of professionals throughout India that time in this domain,” he shares.

Infinyt 3D started with an idea of being a designing studio, where it would specialise in designing new consumable products using 3D printing technology. The challenge faced on that path was getting the idea across to people, as the medium was large unknown to many potential clients. The business then changed its tack, taking a more holistic approach in the 3D printer business. They took up an authorised dealership of 3D printers in Goa, along with other services. Infinyt 3D currently holds reselling rights for products of two pioneering companies in the domain, namely 3D Systems, the company credited with the invention of 3D printing; and Divide By Zero Technologies, one of the first companies in India to manufacture their own printers and market it locally. Other than these two, Infinyt 3D is also a franchisee of the World of Lilliputs (WOL 3D). Through these three names, the company offers printers in the price range of ₹25 thousand to ₹4.5 Crore. They also deal in 3D pens, handheld devices for drawing a 3-dimensional object by hand.

That apart, Infinyt 3D is the only company in Goa to provide professional 3D printing services. It designs products and spare parts as per the needs of other companies. The services offered by them range right from the design phase to manufacturing. For this, they work in collaboration with Thinkerprints, another startup working on the project making 3D printers affordable to the masses. “There have been many companies and startups which have had their prototypes developed by us for various projects and applications. That’s how our service side of the business grew strong,” shares Ryan. The client list of Infinyt 3D include Tata Consultancy Services, Siemens, Crompton, Duraline, Commscope and IFB, among many other. With time, the company has far outgrown its initial idea in terms of both, scale and diversity; and with growing applications of 3D printing technologies, it is only bound to scale up further with time.

That apart, Infinyt 3D is the only company in Goa to provide professional 3D printing services. It designs products and spare parts as per the needs of other companies. The services offered by them range right from the design phase to manufacturing. For this, they work in collaboration with Thinkerprints, another startup working on the project making 3D printers affordable to the masses. “There have been many companies and startups which have had their prototypes developed by us for various projects and applications. That’s how our service side of the business grew strong,” shares Ryan. The client list of Infinyt 3D include Tata Consultancy Services, Siemens, Crompton, Duraline, Commscope and IFB, among many other. With time, the company has far outgrown its initial idea in terms of both, scale and diversity; and with growing applications of 3D printing technologies, it is only bound to scale up further with time.

“There is no dearth of assignments in the present scenario,” says Ryan; “most companies have ongoing research and development projects going on,” he adds. The research and development departments of companies have constant need of prototyping their products to check their viability. Conventionally, the entire process is very long and resource intensive, as there is a need to repeat the entire process for every single change in the model of the product. Over that, if the end product fails, the whole effort including the time and resources invested is rendered futile. To illustrate this, Ryan shares an example of redesigning a container for pills. For this, after the initial design, a wooden model is made. When that is done as per need, it is forwarded to the moulder for creating a mould which would run a cost anywhere between ₹30 to 60 thousand, with a time requirement of about 1 month. After this, through mould injection, the product is prepared. The entire process would cost nothing less than ₹1 lakh on a conseravative estimate. Now if the same is done in a 3D printing machine, it can be done within ₹6000, and in about 1 hour’s time. “This is the major pain point in most of the industries in the manufacturing sector. That is where we come in,” asserts Ryan Vaz.

Another sector in which Infinyt 3D is making its mark is education. “We aim to expose children to the world of innovation at a young age, as it becomes a source of mindset and the way they think.” Under this arm, the company works on creating STEAM Labs in schools, where the acronym stands for S- Science T- Technology E-Engineering A-Arts M-Mathematics. Here they set up labs in schools decked with facilities to boost innovation in children by implementation and application of the practical aspects of science. Each of these labs is provided with Arduino systems among other things, which introduces basic robotics and also a practical understanding of most technologies to students. It provides an opportunity to learn through practical applications too, rather than just dry theory.

Taking the same idea ahead, the company is also working on a concept of ‘Maker’s Space’ in collaboration with CIBA. These would be spaces for the general public with facilities and amenities to try out their innovative ideas or experiments. Any person would be able to subscribe to it and use the facilities on payment of a rent on an hourly basis.

Moreover, they also conduct workshops constantly to spread awareness about 3D printing technology, being the first in Goa to introduce it to kids in Goa. These workshops in schools are free of cost. “I feel more schools must take advantage of these workshops,” says Ryan. “We are also open for internships and encourage students to come and use the facilities at our plant to try out their ideas,” he adds. With respect to the present situation in the education sector, Ryan shared an observation, saying, “It is a sad thing to note that out of the 5 engineering colleges in the state, not even a single one has introduced the use of 3D printing technology either in their curriculums or for their project work, especially when they are the ones who need it the most. Even during workshops, as compared to engineering students, children picked up and implemented the technology in a much better way,” he adds.

Things have taken a turn with the implementation of Atal Tinkering Labs Scheme implemented recently in schools, shares Ryan. Under this scheme, over 16 schools have now been provided with 3D printers and robotics kits. However, the labs’ scheme falls short on its objectives due to a lack of mentors in those labs. Ryan himself is one of the mentors for schools in Goa region appointed by the Neeti Aayog. He further notes that “Changes we see in children who have worked with us is amazing, there is an evident change in the way they think.”

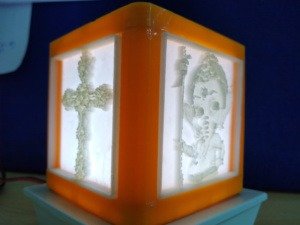

Owing to the applications of 3D printing in various sectors, ranging from medicine, food, heavy industry to jewellery, the technology seemingly has an infinite growth potential. One of the innovative ideas Infinyt 3D has come up with is printing Ganesh deities for Chaturthi celebrations recently which are biodegradable in nature. Made of Polyvinyl Alcohol, which is a biodegradable plastic, these deities dissolve completely when immersed in water. They plan to produce this on a large scale from next year onwards. The plan is also to load lotus seeds within the Ganesh idols.

Going ahead, the company aims to provide unique, one of a kind customized solutions to each individual client; while also exploring the market in Dubai. Infinyt 3D is also equally focussed on education and training.

Illustrating his vision regarding the growth of this domain, Ryan Vaz says, “The technology is growing in the same way as a conventional paper printer once did. Very soon, 3D printers will be as common as that”