Green Building Centre by Alcon Anil Counto Enterprise

The concept of Green Building Centre (GBC) promotes the use of alternate GREEN materials such as fly ash and slag in manufacturing building products started by the ALCON ANIL COUNTO Enterprise, leading manufacturers of building material in Goa, under the leadership of their director, Gaurav Naik Khaunte

Watching dreams, working towards them, fulfilling them and then working towards their betterment is what makes us humans a unique species. One such example of dreams coming true and one that continues striving towards success is the Alcon Anil Counto Enterprise which works tirelessly to come up with innovative technology in making better and more reliable construction materials to ensure optimum safety for you and your loved ones.

Alcon Anil Counto Enterprise started its business in the real estate and construction segment four decades ago. As a part of its backward integration strategy, the group has ventured into manufacturing of construction related products such as cement, concrete, concrete additives as well as aggregates over a period of time. Precast concrete products are another extension of their construction products portfolio which helps in making the construction process much faster and efficient. ACC Ltd. one of the largest cement manufacturers in India has developed the concept of Green Building Centre across India to promote innovative and cost effective housing, infrastructure and road building solutions.

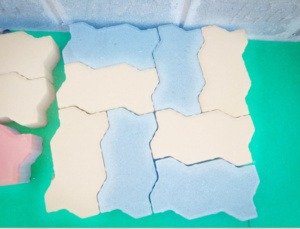

As an added branch of their construction industry business, Alcon has set up a precast manufacturing plant at Kundaim Industrial Estate under the innovative concept of Green Building Centre (GBC). This concept promotes the use of alternate GREEN materials such as fly ash and slag in manufacturing building products such as bricks, blocks, pavers, kern stones, drain covers and flag tiles. At this GBC plant, the company is further developing some unique products which will use the waste/by-products of other industries.

Since every great empire that ever existed started by the laying down of foundation stone, so was GBC, the first step to move ahead was to find the right equipment to provide superior quality and world class products. “We have invested in the latest state of the art automated machinery of European design. We consider our superior plant technology with a strict quality control procedure to be our differentiating factor when compared to other precast manufacturers,” says Gaurav Naik Khaunte, Director, Alcon Anil Counto Enterprise.

But making a project as huge as GBC to work smoothly is no cake walk, it has its own hardships such as timelags due to statutory clearances and approvals; cumbersome administrative processes and other such roadblocks.

The GBC is backed by Alcon’s R&D facility set up in the same complex, which has the latest instruments to help improve the material usage and find new use for green materials, wastes and other industrial by-products – for commercial applications. It has been the DNA of Alcon Group to find unique solutions with different materials for use in construction. They already hold patents for innovative products developed for use in high performance concrete. Developing and building the right infrastructure to carry out their R&D initiatives also took a lot of time and learning.

Going with the same philosophy, various new alternates are being explored for numerous wastes and by- products of industry to find a good and sustained use. Many of these innovations will be used in the GBC to make the products much better and green.

According to Gaurav Khaunte, their plant being inaugurated by stalwarts like Suresh Prabhu, Minister of Commerce

and Industry and Civil Aviation, Govt. of India; Neeraj Akhoury, Managing Director of ACC Ltd. and the then PWD minister of the Goa Government, Sudin Dhavalikar, has been one the most memorable incidents of this project.

Talking of the future, a few projects which are the under pipeline and at various stages of implementation.

In going with the ALCON philosophy of doing things first and out of the box, the company plans to come up with plaster and mortars for the construction industry with specialized applications. The products being planned will greatly enhance the efficiencies of construction. Easy to use repair products are being planned to be introduced into the market. The project has commenced and in a few months it will be introduced in the market.

The company is also working on projects of bio toilet and bio digesters used to convert waste to manure